Production

Mikrut’s production activities are mainly export-oriented. The main recipients of our products are German, Swiss and Austrian companies, with whom we have been cooperating for many years. In the course of this cooperation, we have become known as reliable, solid and accurate business partners. Our constantly growing product range currently includes more than 300 different products.

There is also cooperation with local companies for some services.

Upon individual customer request, we can prepare construction documentation together with the technology for manufacturing the products.

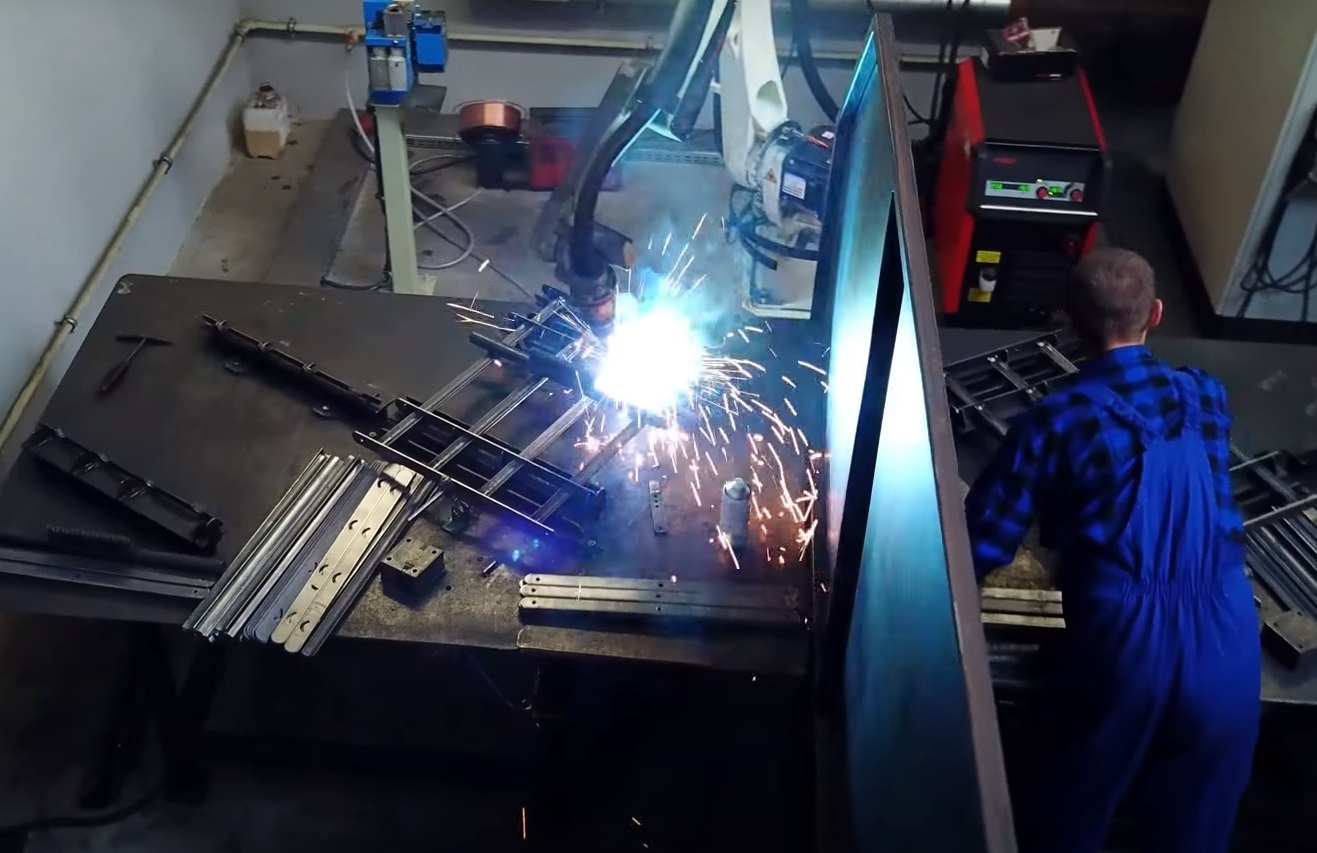

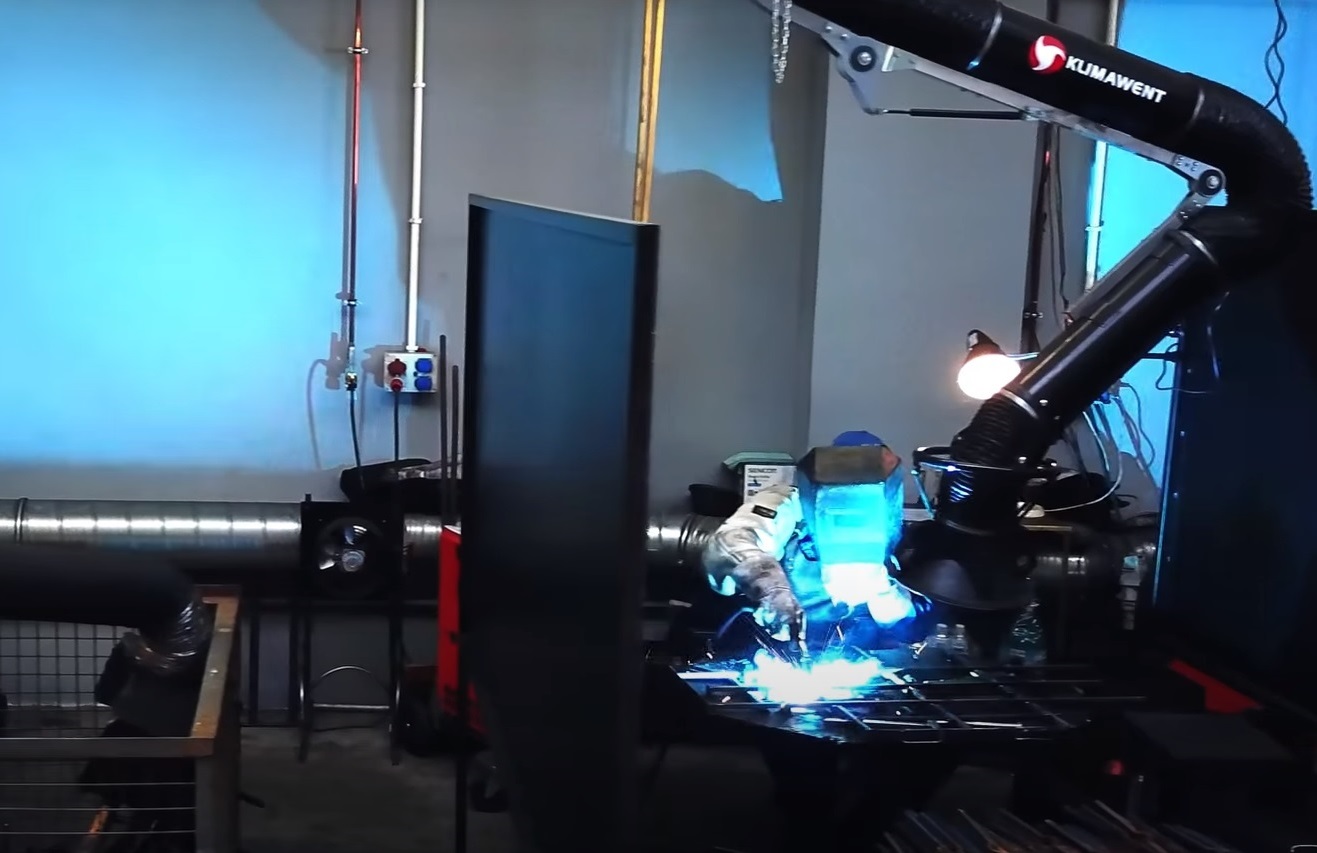

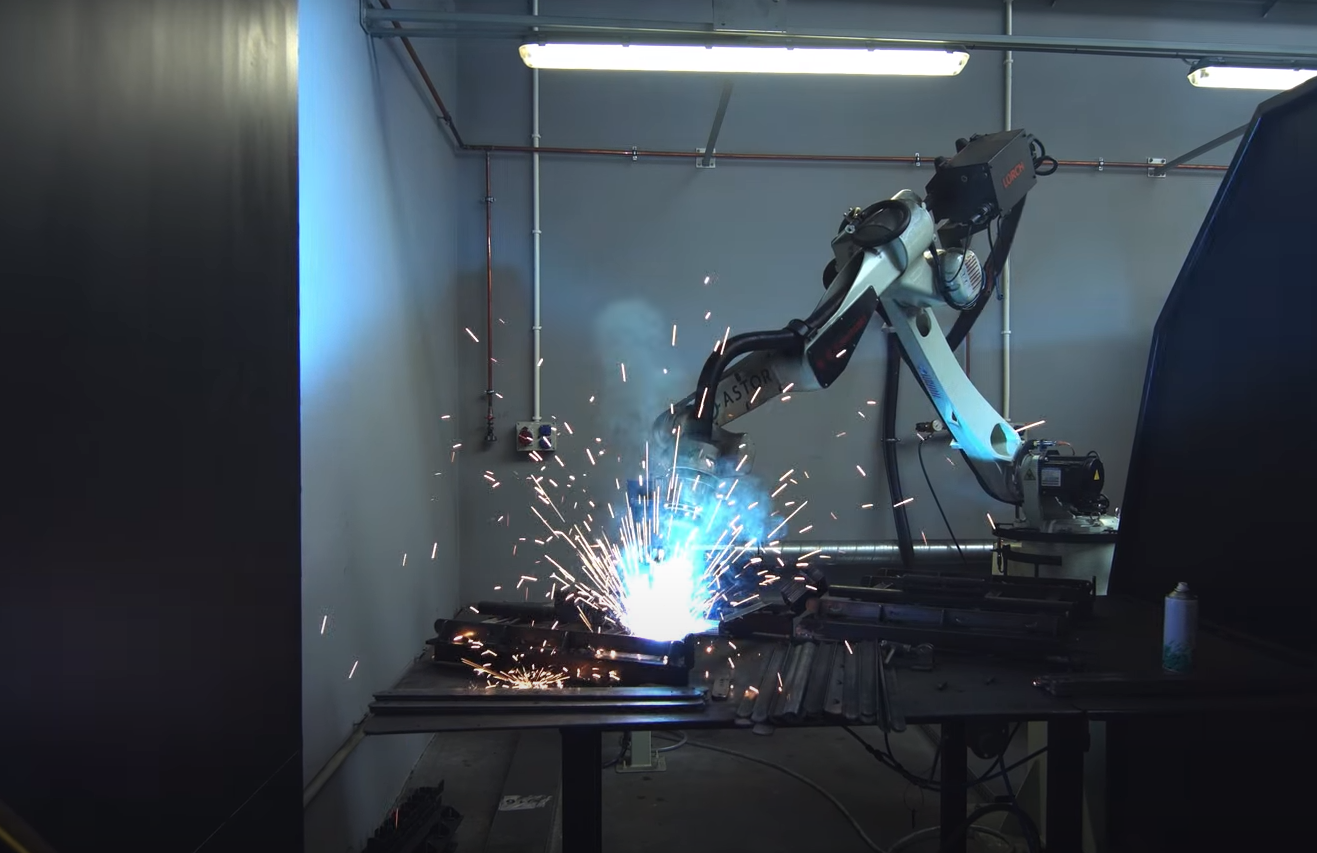

Welding

We weld ordinary and stainless steel as well as aluminium in a noble gas shield. The process itself is greatly improved by the equipment we own, above all the Kawasaki welding robot for series production, as well as Italian semi-automatic rotary welding machines. We also carry out traditional welding with MIG/MAG equipment from Lorch. We have now ordered our first laser welding machine.

Cutting

We have guillotine shears for cutting sheets with a maximum thickness of 6.3mm and a maximum length of 3150mm.

Cutting on band saws of sections and profiles of steel and non-ferrous materials in automatic and semi-automatic cycle.

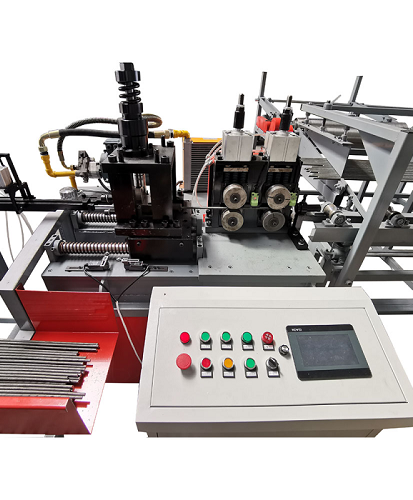

Punching and bending

We offer punching of parts on eccentric and hydraulic presses with pressures from 6 to 120 tonnes.

An automatic line from the Italian brand Herrblitz for punching from strip up to 300x5mm together with an Italian eccentric press from Omer.

Sheet metal bending is enabled by a CNC bending machine and an automatic press brake. We have recently purchased a laser punching machine with the ability to punch carbon sheets up to 16mm thick.

Riveting

We rivet using traditional and rotary methods.

Surface treatment

Our products can be, according to customer preference:

- hot-dip galvanised or electroplated,

- chromium-plated,

- nickel-plated,

- cataphoretic painted (KTL),

- vibration-treated,

- powder-coated,

- sandblasted.

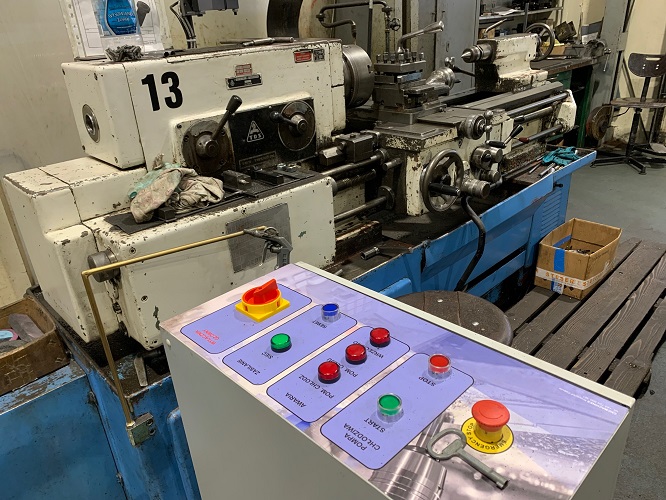

Machining

We offer machining on CNC and conventional machines:

- Haas DS30Y twin-spindle machining centre

- Pinacho ST-285

- CNC vertical milling machine JAFO FVF 45N

Kawasaki welding robot

Scope of production:

- production of brackets, building hardware, as well as fences. In particular: stops, hinges, brackets, hooks, latches, bolts for doors and gates, etc.

- manufacture of components for glider trailers such as: wing carriers, wing supports of various shapes and sizes, hydraulic ramps, drawbars, etc.

- manufacture of height-adjustable shelves for flower displays

- various types of bicycle racks made of tubes or profiles

- common and stainless steel fencing components: posts, connectors, post caps in aluminium or non-ferrous metals, entrance gates, etc.

- construction accessories

- stop hooks in various lengths

- massage tables and chairs

- semi-automatic cutting of bars and flat bars of various cross-sections.

- induction heating of materials to be bent

- CNC sheet metal bending